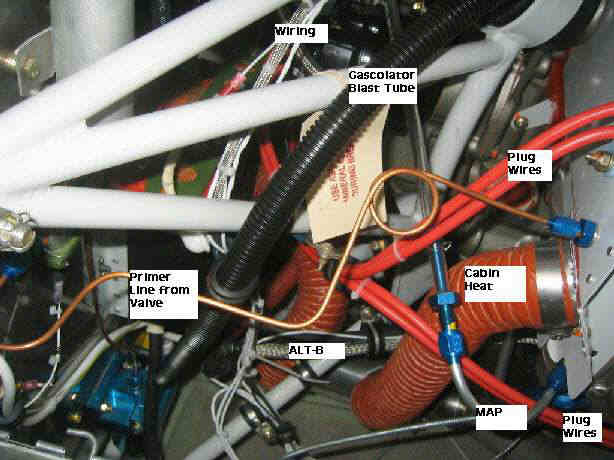

I read through all the posts about the pros and cons of primers and learned a lot... this lead me to investigate the installation of the primer in my T-18.

I noted immediately that the lines are plastic and wondered if that was OK.

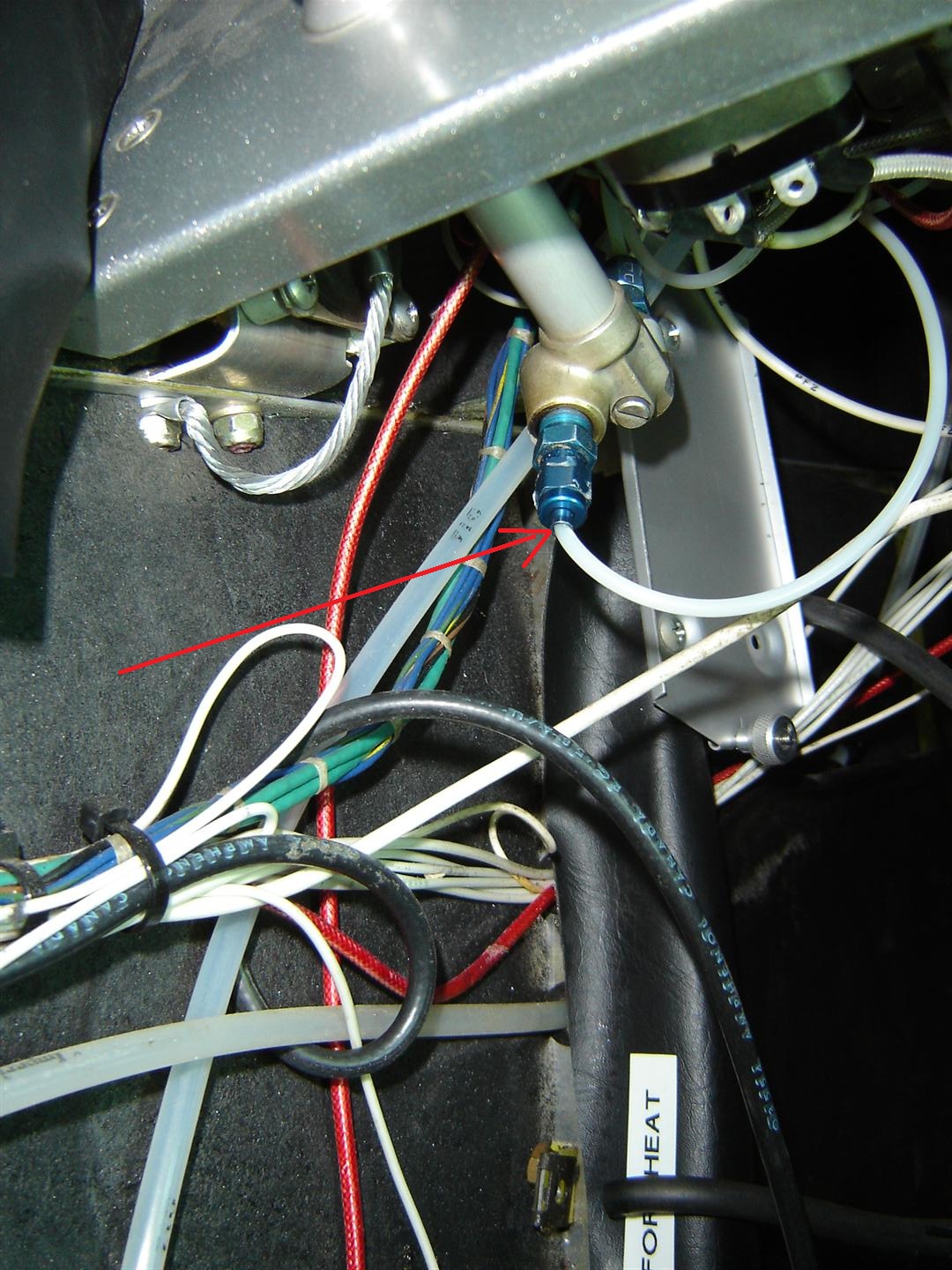

While not very happy about having fuel lines in the cockpit at all was even more concerned when I noted the lower line (in or out???) had a definite crease where it exits the coupling and curls upward, see photo.

This seems to me to be a point of impending failure or at the least if it doesn't weaken the tube wall would restrict the flow.

I know nothing about primers (other than the previous threads) and am cornered about getting my left pant leg caught on this tube and tearing it out of the primer or having it just fall out of its own volition.

I was considering building a guard panel that extends from the panel lip rearward to protect the primer; is that needed?

Any thoughts

Image Insert: