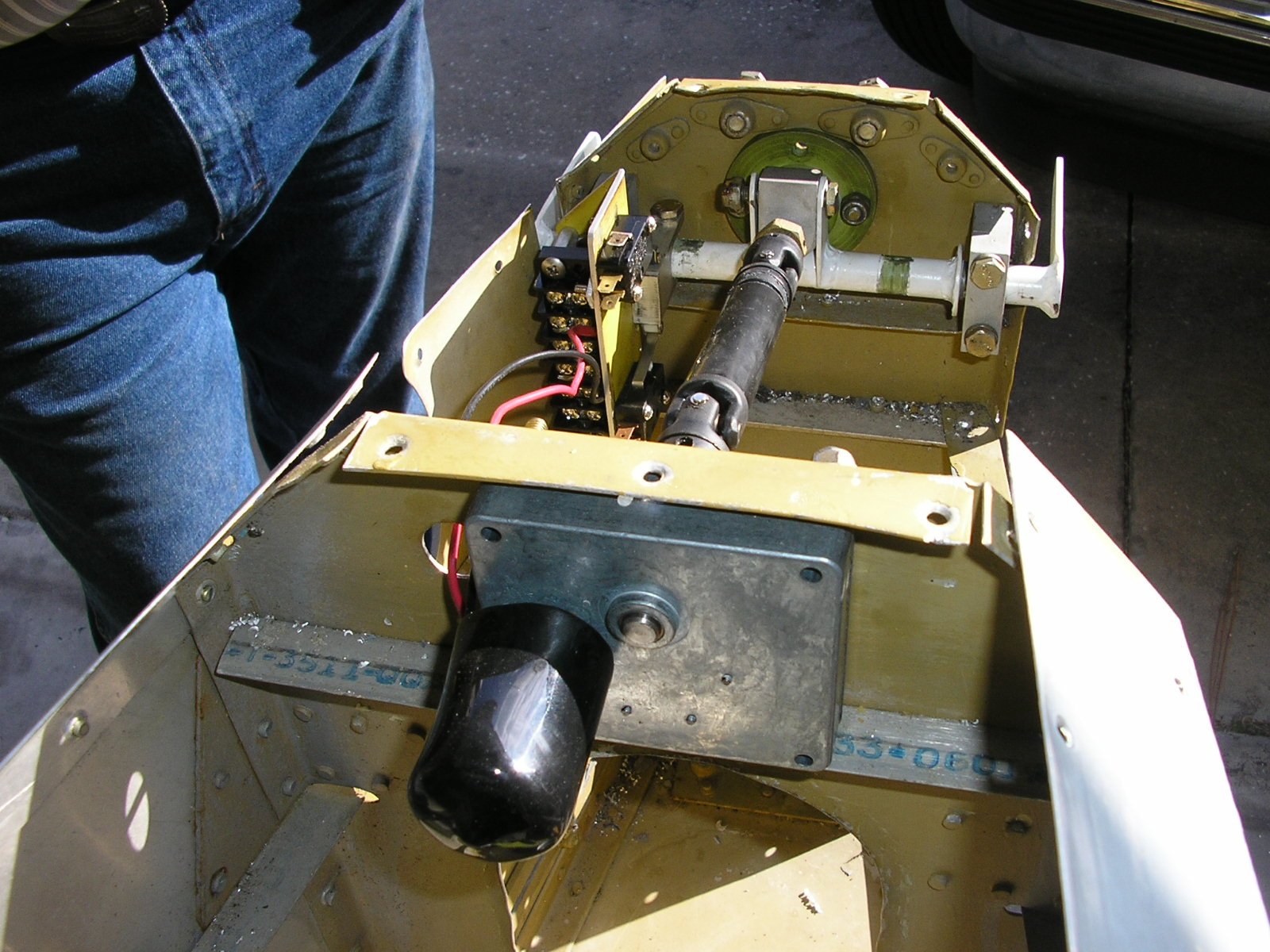

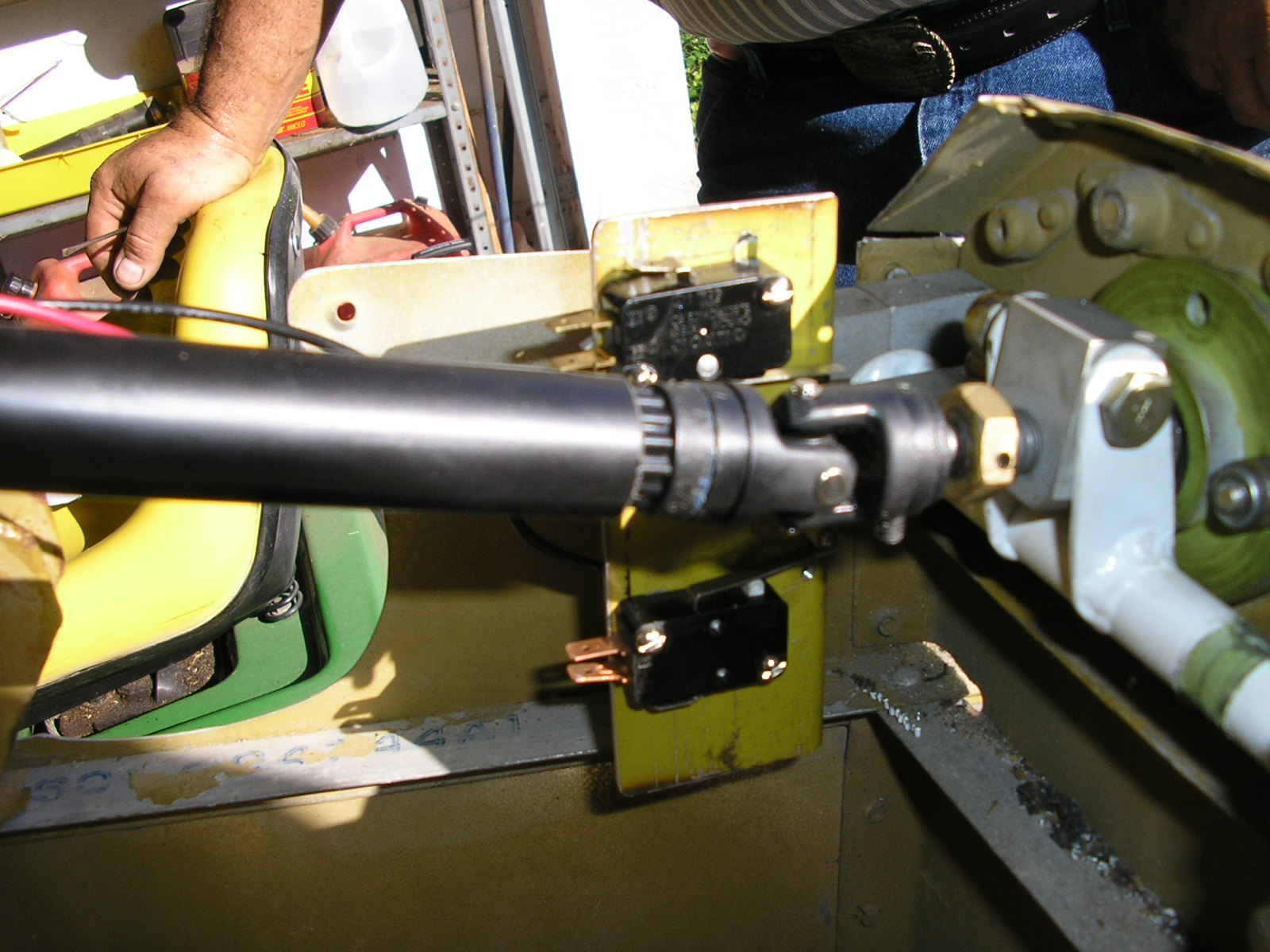

This is a trim Bob and I came up with. Look at the photo album, open up fytrplt album and look at images 007,008,009. We used a universal shaft from a RC model truck, TRAXXAS #5451X and #5458X yoke, a Graingers motor, 2L009, and micro switches from radio shack. The wiring diagram is in my photo album. The flex shaft "IS" a must. As destortion will occur at this point.

My math always adds up to Naught from Naught is Naught !

My math always adds up to Naught from Naught is Naught !