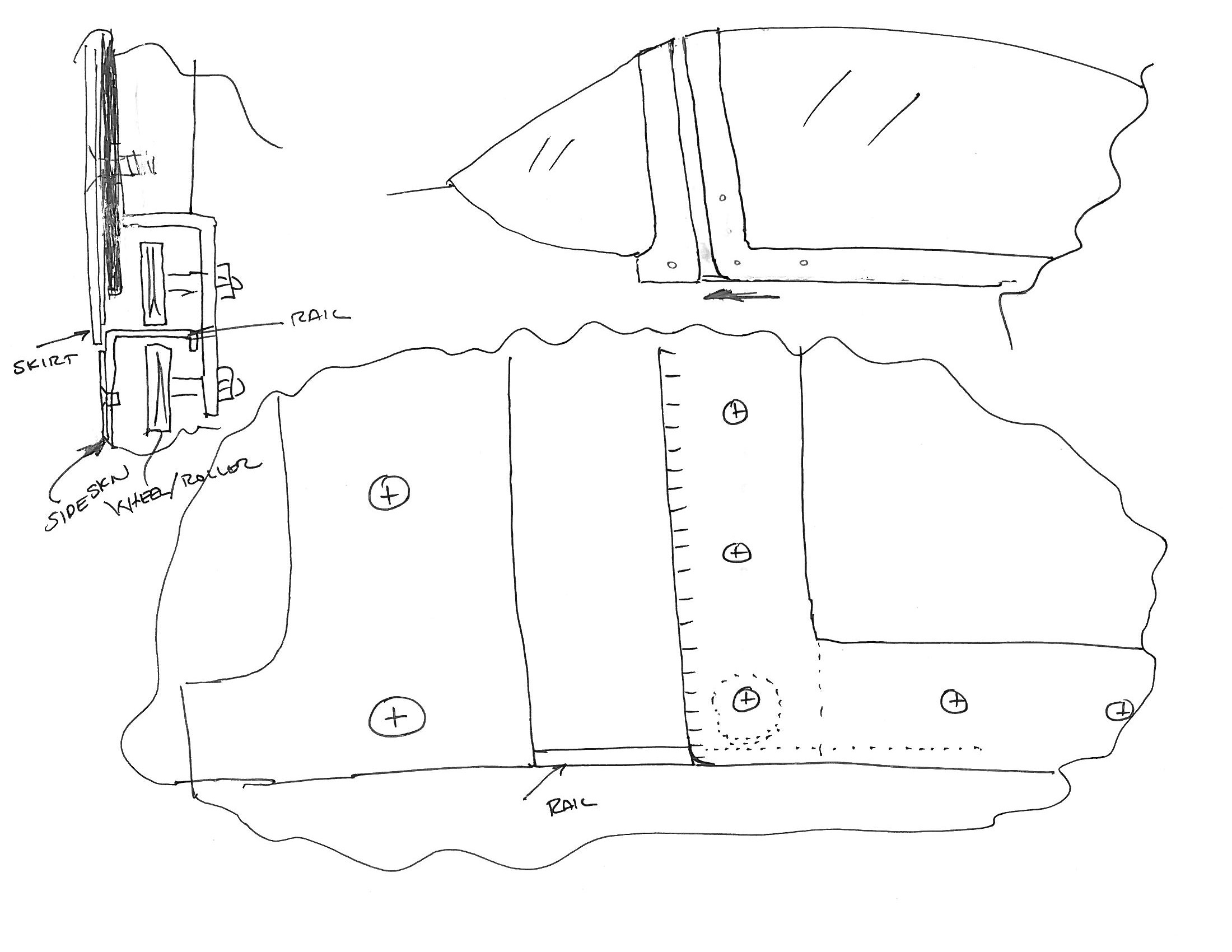

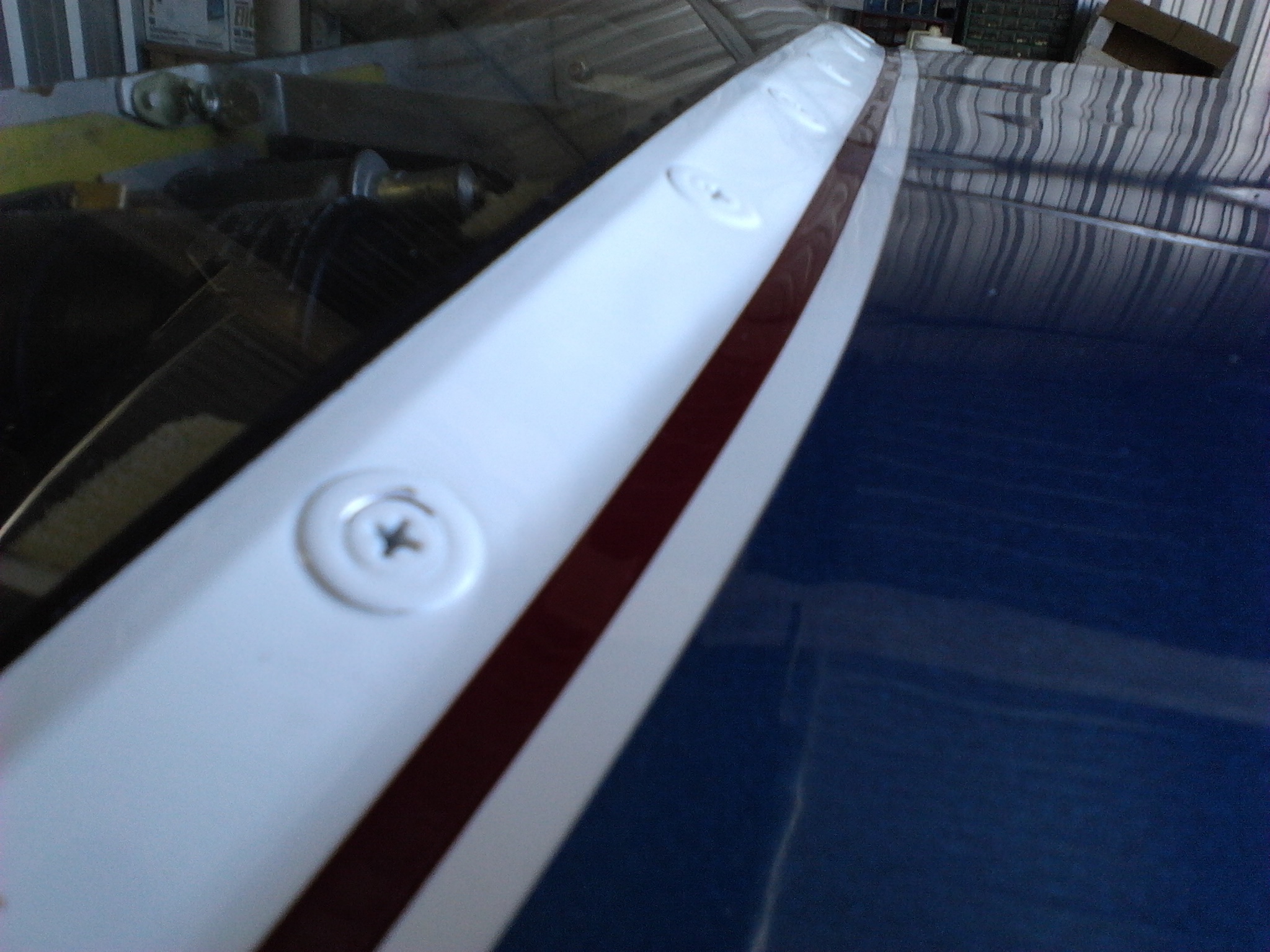

Did you mean this area ? I did not use a foward trim strip on the windshield. The over the top piece I tucked in between the skin and the roll bar. I also put a beveled edge on all my trim strips. To do that I modified an edge roller with a hardwood guide so I could clamp it into a vise and pull the entire length of the trim strip thru it, thereby maintaining a constant edge. [:p]

RB

Image Insert: